Save time and keep waste costs low when performing quantitative analyses or storing materials. Our silane glass sample bottles were treated by vapor deposition silane method. Surface passivation treatments such as silanization and silicification are essential to maintain the integrity of certain materials or extracts stored in glass containers. Surface modification can reduce the active sites on the borosilicate glass surface.

The process of surface treatment of metallic or non-metallic materials with aqueous organosilane as the main component. Silanization has the following advantages over conventional phosphating: no harmful heavy metal ions, no phosphorus, and no need for heating. The silane treatment process does not produce sediment, the treatment time is short, and the control is simple. The processing steps are less, the table adjustment process can be omitted, and the tank liquid can be reused. Effectively improve the adhesion of paint to the substrate. Collinear processing of iron sheet, galvanized sheet, aluminum sheet and other substrates.

(1) Silane treatment does not contain harmful heavy metals such as zinc and nickel and other harmful components. Nickel has been proved to be harmful to the human body. The World Health Organization (WHO) stipulates that nickel should be discharged to zero after 2016, requiring that nickel should not be contained in phosphating wastewater, phosphating vapor and phosphating grinding dust.

(2) Silane treatment only produces a very small amount of silane slag, and the slag treatment cost is very low.

Phosphating slag is the inevitable companion of traditional phosphating reaction. For example, an automobile production line using cold rolling plates will produce about 600g of phosphating slag with 50% moisture content per processing 1 car (measured by 100m2), and a production line of 100,000 cars will produce 60t of phosphating slag per year.

(3) No nitrite promoter is needed, thus avoiding the harm of nitrite and its decomposition products to the human body.

(4) The product consumption is low, only 5% ~ 10% of phosphating.

(5) There is no process such as table adjustment and passivation in silane treatment. Fewer production steps and shorter processing time are helpful to improve the production capacity of the factory, shorten the new production line, and save equipment investment and floor area.

(6) The room temperature is feasible, saving energy. Silane tank solution does not need to be heated, and traditional phosphating generally requires 35 ~ 55℃.

(7) There is no conflict with the existing equipment process, and no equipment transformation can be directly replaced by phosphating; It is compatible with the original coating process and can be matched with all types of paint and powder coating used.

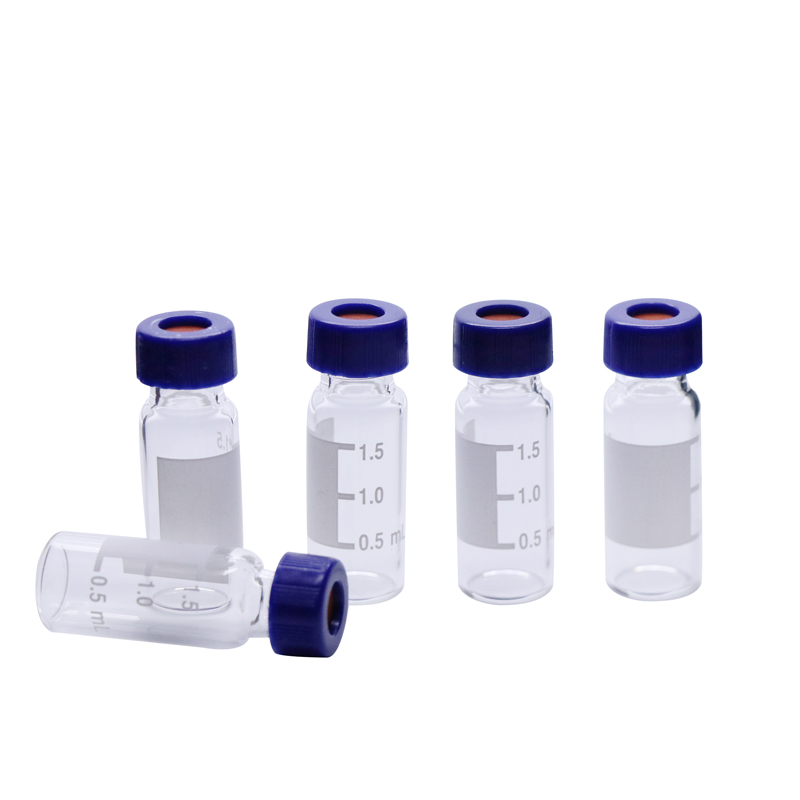

Borosilicate glass is a popular material for HPLC vials because it has excellent chemical and thermal resistance properties. This type of glass is well suited for HPLC applications because it can withstand the high temperatures and strong solvents that are often used in HPLC.

When selecting HPLC vials, it is important to consider the type of sample being analyzed and the conditions under which the analysis will be performed. Amber borosilicate glass HPLC vials with a 9mm opening are a popular choice for many laboratory applications due to their excellent performance characteristics and compatibility with a wide range of samples and conditions.

In addition to the vial itself, a septa is also required for HPLC analysis. The septa is a small, circular piece of material that fits into the vial and acts as a seal. It allows for the introduction of the sample into the vial and also provides a barrier between the sample and the HPLC syringe, preventing contamination. When selecting septa for HPLC vials, it is important to consider the type of sample being analyzed and the conditions under which the analysis will be performed.

Post time: Mar-30-2023